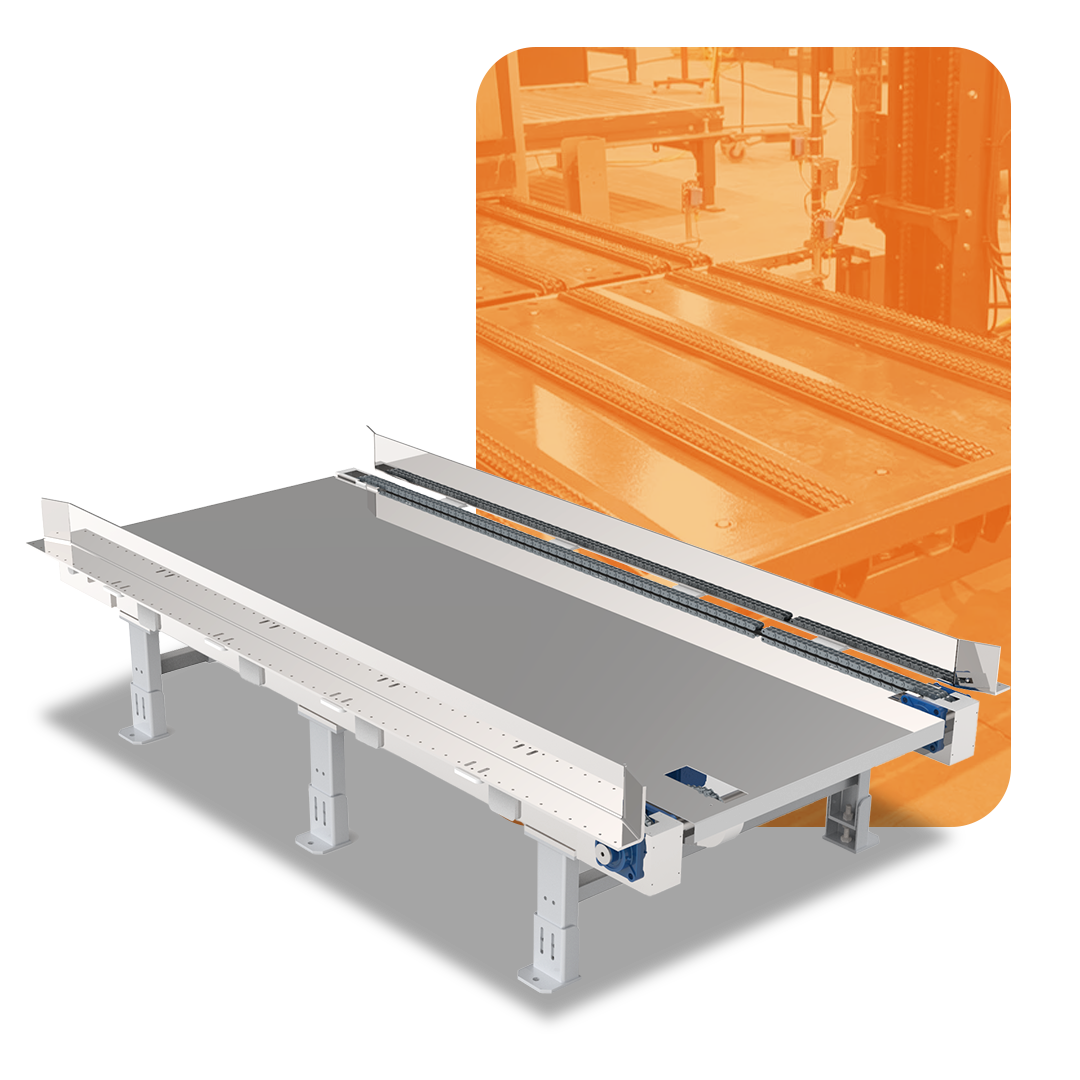

Chain Conveyor

A Chain Conveyor is a rugged, reliable material handling system designed to move heavy or bulky loads across production lines or warehouse zones using hardened steel chains instead of belts or rollers. It is ideally suited for transporting pallets, containers, industrial parts, racks, or large components where traditional conveyors may not be sufficient.

Chain conveyors are commonly used in assembly lines, automotive manufacturing, paint booths, and warehouse pallet transfer zones due to their ability to handle high loads, harsh environments, and non-uniform surfaces. These systems can be installed at floor level, recessed in pits, or elevated, and are compatible with automated transfer systems and palletizing cells.

Heavy Load Handling

Transports pallets, containers, and industrial items up to several tons.Durable Chain Drive

Uses double or triple-strand steel chains for high strength and long service life.Low Maintenance Operation

Simple mechanical design with minimal moving parts and easy serviceability.Flexible Configuration

Available in 2-strand, 3-strand, and multi-strand formats for various load sizes.Floor or Pit Mounted

Can be integrated into recessed or elevated layouts depending on workflow.Automatable

Easily integrates with PLCs, sensors, WMS/WCS, and robotic palletizers.

| Length of the Conveyor | 1000 to 3000mm |

| Conveyor Width | Euro /ISO Pallet / Customize up to 2000mm |

| Conveyor Height | 400 to 850mm / Customized |

| Conveyor Speed | 30 m/min |

| Payload | Up to 3000 Kg |

| Structure | M S Powder coated |

| Drive System | Chain Sprocket |

| Motor | SEW/Bonfiglioli/Reputed |

| Noise | Below 60 DB |

Applications

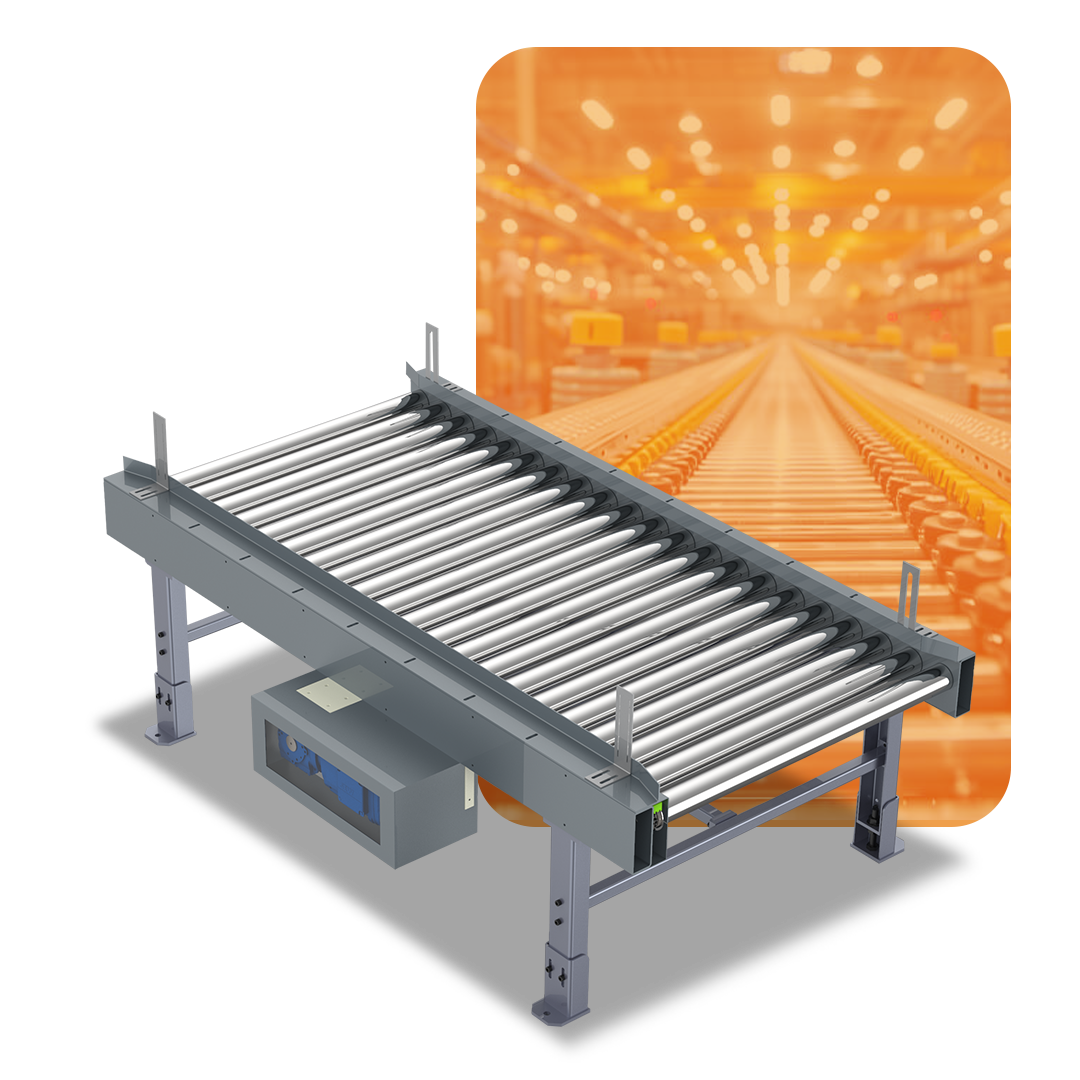

Roller Conveyor

The Roller Conveyor is a versatile and durable material handling solution designed for the smooth transport of goods across short to medium distances in a facility. Available in gravity-driven or motorized (powered) configurations, roller conveyors are used for moving boxes, cartons, totes, pallets, and other flat-bottomed materials efficiently and reliably.

Roller conveyors are ideal for applications involving sorting, assembly, packaging, accumulation, and transfer, and can be configured in straight or curved paths. Whether manual or automated, they improve material flow, reduce manual handling, and can be seamlessly integrated into production lines, warehousing, or distribution systems.

Modular Design

Easily customizable length, width, and configuration to suit different layouts.Gravity or Powered Operation

Available as manual (gravity-fed) or motor-driven for automation-ready applications.Smooth Material Flow

Efficient movement of loads with minimal resistance and reduced manual handling.High Load Capacity

Handles small cartons to heavy pallets with the right roller diameter and pitch.Durable Construction

Built from stainless steel, galvanized steel, or aluminum for long-term performance.Flexible Integration

Compatible with sensors, stoppers, side guides, and transfer mechanisms.

| Length of the Conveyor | 500 to 3000mm |

| Conveyor Width | Euro /ISO Pallet / Customize up to 2000mm |

| Conveyor Height | 400 to 850mm / Customized |

| Conveyor Speed | 30 m/min |

| Payload | 500 to 3000kg |

| Roller Dia | 50 to 130mm |

| Structure | M S Powder coated |

| Drive System | Chain /Pulley |

| Motor | SEW/Bonfiglioli/Reputed |

| Noise | Below 60 DB |

Applications

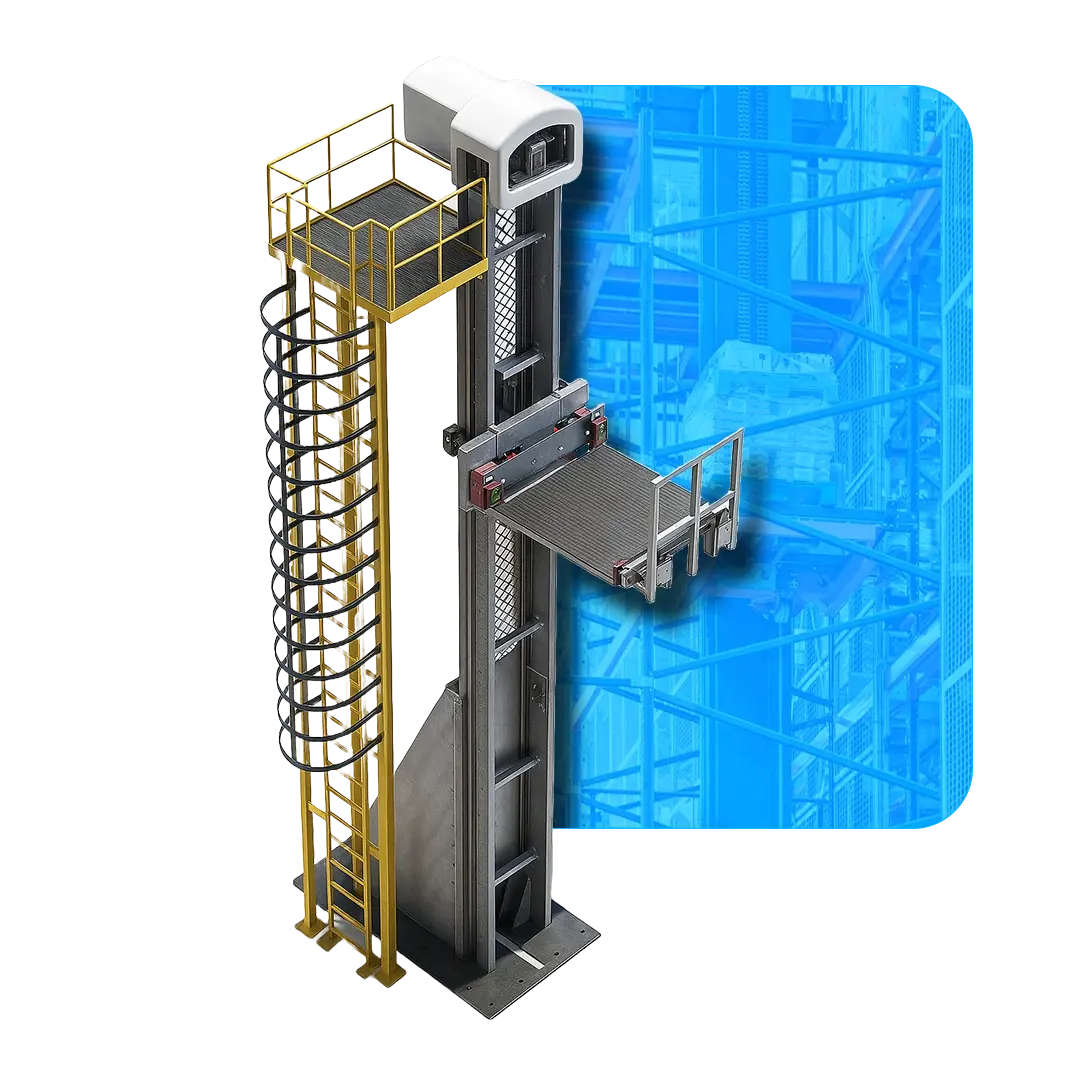

Pallet Lifts

Pallet Lifts are robust vertical lifting solutions designed to raise and lower palletized goods safely and efficiently between different heights or floors in industrial and warehouse environments. Engineered for heavy-duty use, these lifts enable smooth vertical transportation of materials with minimal human effort, reducing reliance on forklifts or manual handling. They are ideal for loading docks, mezzanines, production lines, and racking systems where frequent pallet movement is required.

Available in hydraulic, mechanical, or scissor-lift configurations, pallet lifts are built to handle weights from a few hundred kilograms up to several tons. With advanced safety features, customizable platform sizes, and integration capabilities with conveyor systems or automation lines, pallet lifts are a cornerstone of modern material handling and vertical goods flow in high-throughput environments.

High Load Capacity: Designed for lifting loads ranging from 500 to 1500 kg, and customizable up to 3000 kg+

Customizable Platform Size: Tailored to suit various pallet dimensions.

Multiple Drive Options: Available in hydraulic, mechanical screw, or chain-driven formats.

Compact & Space-Efficient: Vertical design saves valuable floor space.

Safety Systems: Includes anti-drop locks, emergency stop, safety rails, and interlocks.

Easy Integration: Works with conveyors, AGVs, and warehouse automation.

Optional Enclosures: For added safety and environmental protection.

| Parameter | Specification |

|---|---|

| Pallet Size | Euro / ISO Pallet |

| Lift Height | Up to 15 mtr. |

| Horizontal Speed | 30 m/min |

| Vertical Speed | 60 m/min |

| Load Capacity | Up to 1500 Kg customizable up to 3000 kg+ |

| Motor and Gear Box | MDR / SEW / Bonfiglioli / Reputed |

| Drive System | Chain / Belt |

| Lift Column | Single / Four |

| Structure | M S Powder Coated |

| Control Method | HMI |

| Noise | Below 70 DB |

| Safety System | Free Flow |

| Number of Cycles | 60 / 120 per hour |

Applications

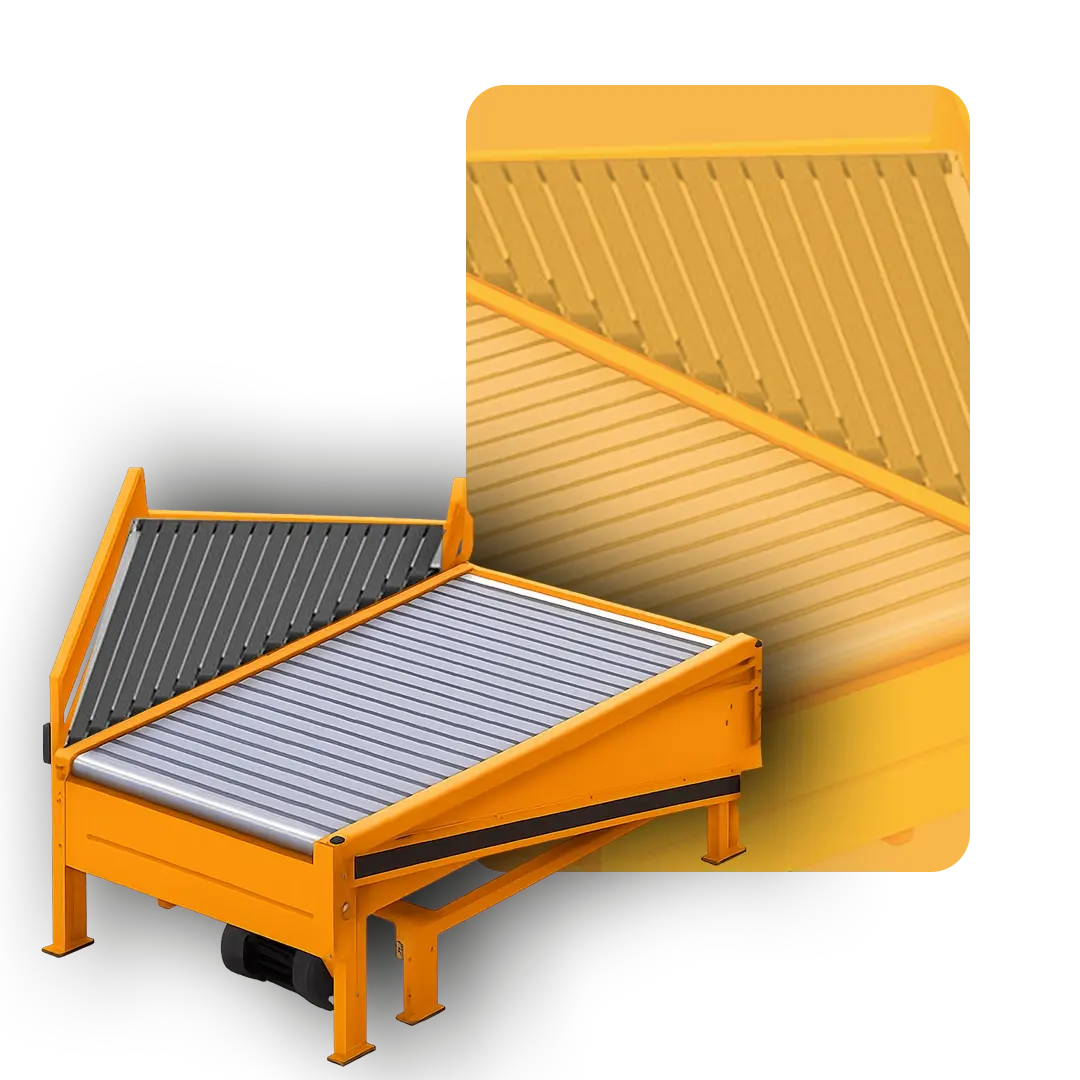

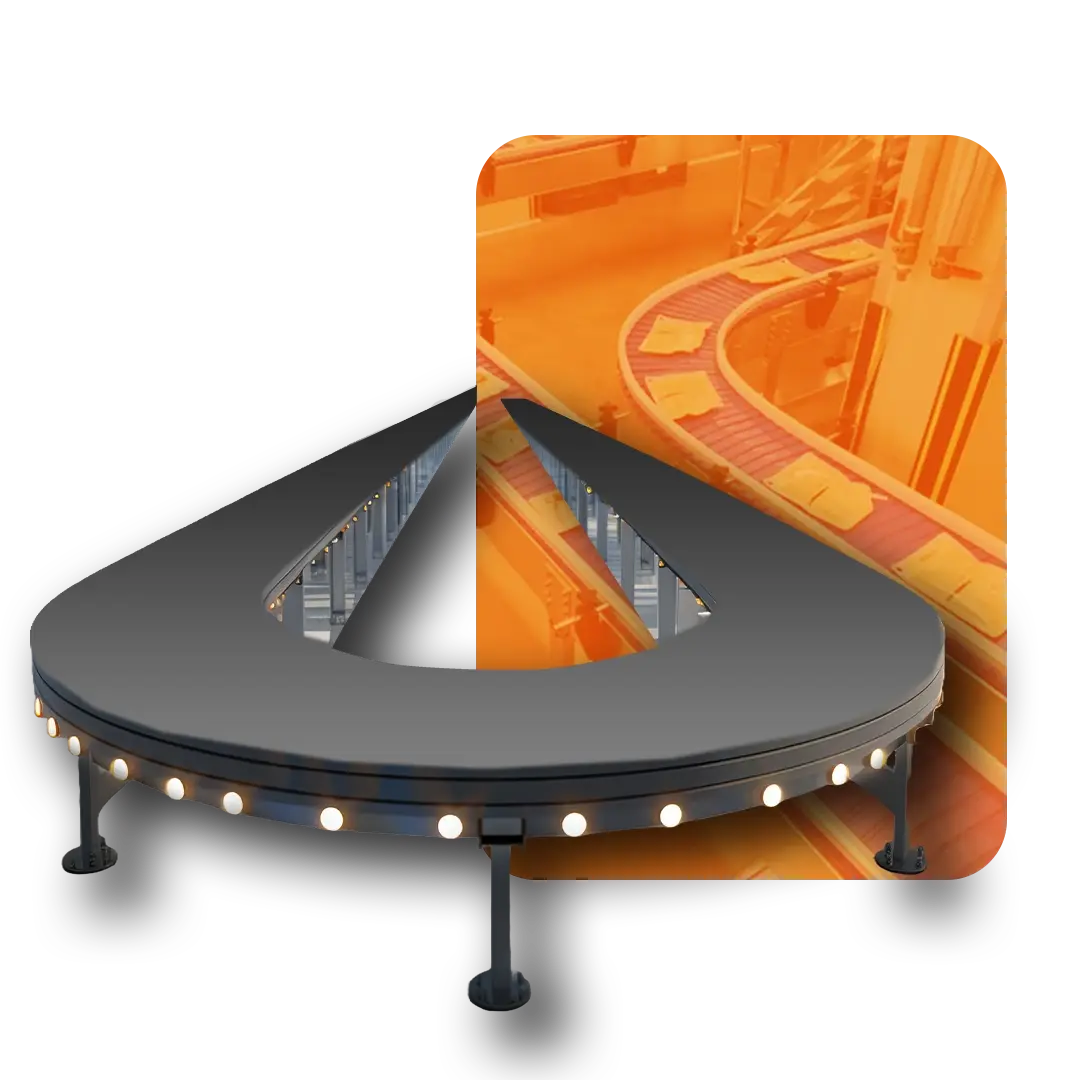

Turn Table

Turn Table Conveyors are innovative conveyor systems designed to rotate loads to change their direction of travel without manual intervention. They enable a smooth 90°, 180°, or even 360° rotation of pallets, cartons, or totes while remaining in a stationary or moving position. Turn tables are commonly used at junction points within automated conveyor lines, providing flexible routing while saving space and reducing the need for complex transfer mechanisms.

Built with motorized or manual rotation mechanisms, these conveyors can be integrated with roller, chain, or belt conveyors, allowing material to be redirected while maintaining orientation or alignment. Ideal for systems that require angular change in material flow, such as corner turns, divergence routes, or buffer zones, turn table conveyors play a vital role in modern automated logistics and manufacturing environments.

90°, 180° or Custom Rotation: Precise directional control of conveyed items.

Heavy-Duty Load Support: Designed for pallets, totes, or large cartons.

Smooth & Controlled Rotation: Electric or pneumatic drive for accurate turning.

Integrated Conveyor Surface: Roller, belt, or chain options based on load.

PLC & Sensor Compatible: Can be automated for intelligent routing.

Compact Design: Saves space compared to curves or crossover conveyors.

| Parameter | Specification |

|---|---|

| Length | Up to 2000 mm |

| Width | As per Pallet / Required |

| Conveying Speed | 30 m/min |

| Payload | 500 to 1200 Kg |

| Structure | M S Powder Coated |

| Motors | MDR / SEW / Bonfiglioli / Reputed |

| Drive System | Gear and Pinion / Chain / Belt |

| Noise | Below 60 dB |

| Rotation Speed | 4 to 5 seconds for 90° rotation |

| Control Method | PLC & VFD Controls |

Applications

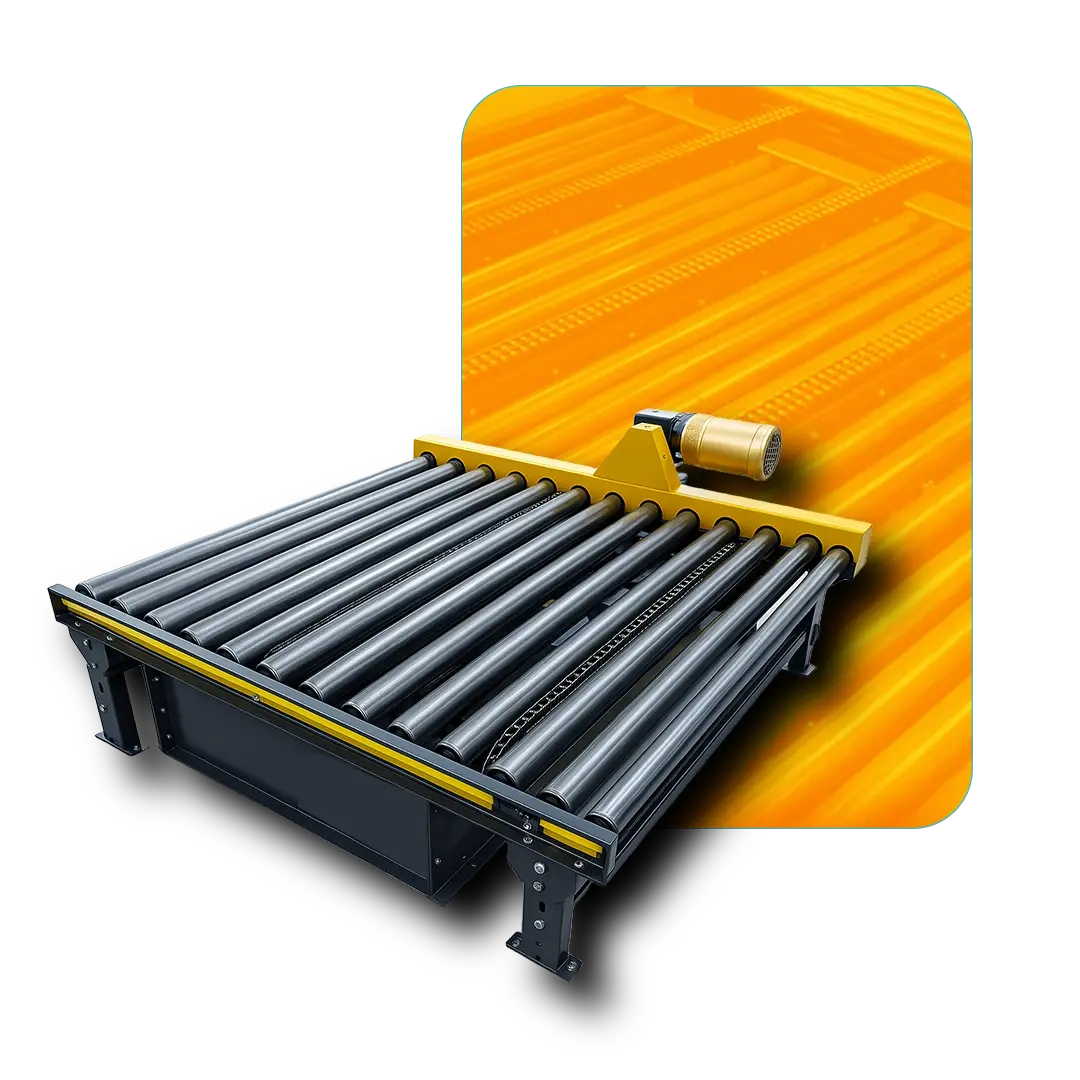

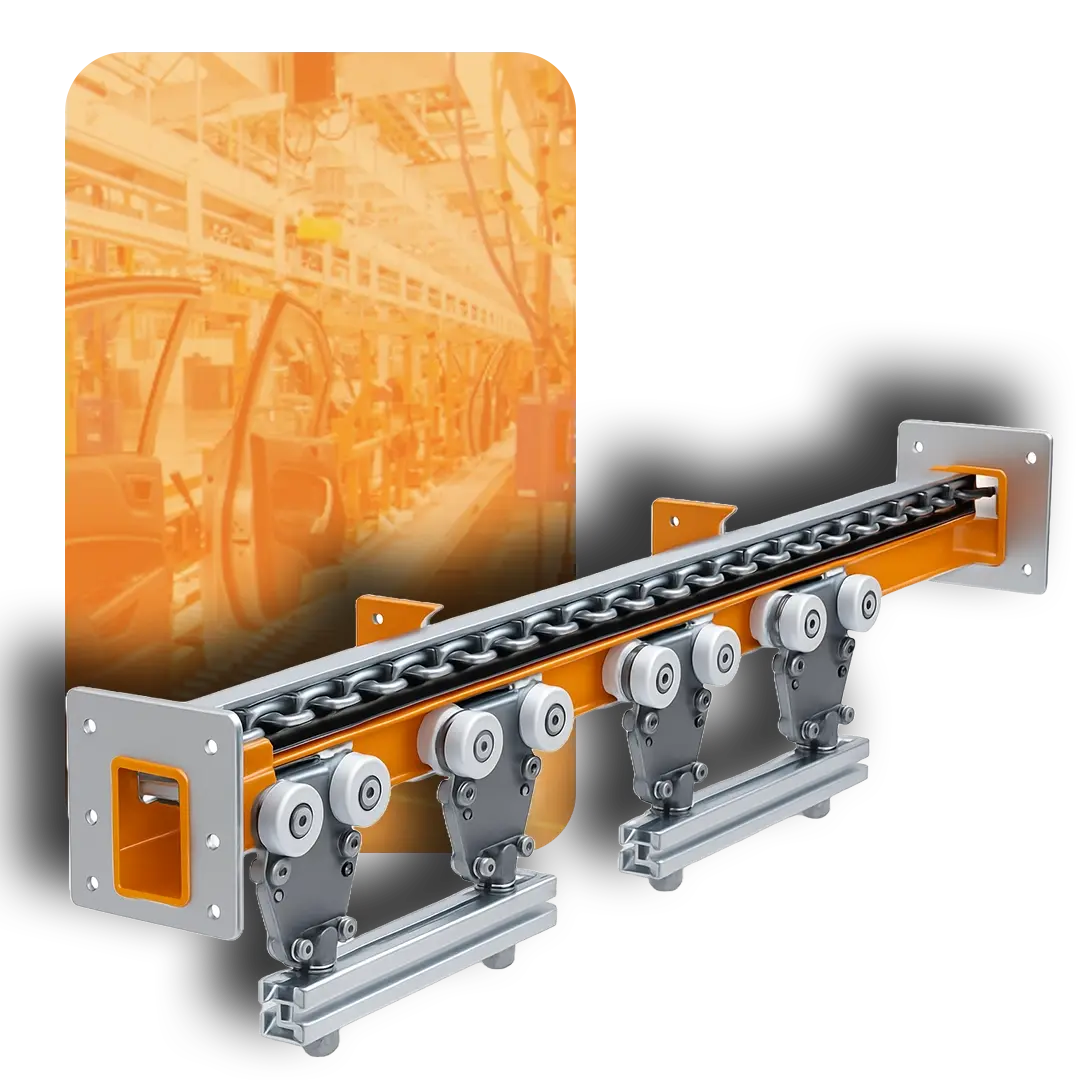

Chain Transfer Conveyor

Chain Transfer Conveyors are heavy-duty material handling systems used to move pallets, containers, or heavy loads at a right angle to their original travel direction. These systems use lift-and-transfer mechanisms that raise products above the primary conveyor and transfer them sideways via robust roller chains. Chain transfers are ideal for routing, merging, diverting, or buffering operations in pallet-based or heavy-load conveying environments.

Built for high reliability and precise alignment, chain transfer conveyors are a key component in automated warehouse systems, pallet handling lines, and assembly operations. They help optimize floor space and streamline multi-directional flow, especially in zones that require intersection control, parallel movement, or multi-line integration.

Right-Angle Transfer: Redirects pallets or loads 90° for efficient flow.

Lift & Transfer Mechanism: Raises product above rollers for clean side transfer.

Heavy-Duty Chain Drive: Ideal for rugged use and long lifecycle performance.

High Load Capacity: Handles loads up to several tons per unit.

Smooth & Accurate Movement: Prevents load shifting during transfer.

Automation-Ready: Integrates with PLCs, sensors, and automated lines.

| Specification | Details |

|---|---|

| Transfer Angle | 90° (custom angles on request) |

| Load Capacity | Up to 2000 kg per transfer |

| Chain Type | Duplex roller chain / Triple chain |

| Actuation Method | Pneumatic or electric lift & motorized chain |

| Transfer Speed | 8 – 20 m/min (variable) |

| Conveyor Compatibility | Roller, chain, or belt systems |

| Frame Material | MS powder-coated / Stainless Steel |

| Safety Features | Limit switches, guards, overload protection |

Applications

MDR-DC Conveyor

The MDR-DC Conveyor is a modular, energy-efficient conveyor system powered by low-voltage DC motorized rollers. Each zone within the conveyor is driven by a dedicated brushless DC motor, allowing for precise control, zero-pressure accumulation, and energy-saving idle modes. Unlike conventional conveyors, MDR systems eliminate the need for complex mechanical transmissions, belts, and chains—making them cleaner, quieter, and safer.

These conveyors are ideal for parcel handling, order fulfillment, packaging lines, and warehouse automation, where flexibility, scalability, and reliability are crucial. With intelligent zone control, MDR-DC conveyors offer automated start/stop functionality, variable speed, and direction control, integrated easily with PLCs, sensors, or WCS platforms.

Energy-Efficient Operation

Rollers activate only when needed, significantly reducing power consumption.Zero Pressure Accumulation (ZPA)

Prevents product collisions with smart zone-based start/stop logic.Low Noise & Low Maintenance

Quiet, beltless design with fewer moving parts minimizes wear and servicing.Modular & Scalable Architecture

Easy to reconfigure or expand zones without system overhaul.Integrated Control Logic

Compatible with PLCs, IoT modules, or independent zone controllers.Safe Low-Voltage Operation

24V/48V DC power supply ensures safer work environments.

| Conveyor Width | Width 300 to 1200mm |

| Conveyor Height | 400 to 850mm / Customized |

| Conveyor Speed | Speed up to 90m/min (model-specific) |

| Payload | 10 to 100 Kg |

| Roller Dia | 38 to 60 mm |

| Structure | M S Powder coated/ S.S |

| Length of the Conveyor | 500 to 3000 mm |

| Drive System | MDR |

| MDR | Anzo/Itoh Denki/Interroll/Pulse |

| Control Card | Anzo |

Applications

Telescopic Conveyor

Telescopic Conveyors are extendable belt conveyor systems designed to load and unload goods efficiently from trucks, trailers, and containers. Featuring multiple sliding sections that extend like a telescope, these conveyors provide a flexible and ergonomic solution for reaching deep into the loading bay, reducing the need for manual handling and streamlining the logistics workflow.

Built for reliability and ease of operation, telescopic conveyors are commonly used in warehouse docks, logistics hubs, courier centers, and retail distribution units. These conveyors drastically improve turnaround time, reduce labor fatigue, and increase workplace safety. Available in motorized or manual extension options, they can be customized with height adjustment, mobile frames, lighting, and operator platforms.

Extendable Length: Multiple stages extend and retract based on truck/container depth.

Easy Loading/Unloading: Reduces manual labor and speeds up operations.

Height Adjustability: Optional hydraulic or electric lift for ergonomic alignment.

Reversible Operation: Enables loading and unloading in both directions.

Safety Features: Emergency stops, anti-collision sensors, and handrails.

Plug-and-Play Design: Quick to deploy and reposition across docks.

| Specification | Details |

|---|---|

| Conveyor Type | Telescopic Belt Conveyor |

| Extension Range | 6 – 20 meters (customizable) |

| Belt Type | PVC / PU / Rubber Belt |

| Load Capacity | Up to 50 kg/meter |

| Speed Range | 10 – 40 m/min (variable speed) |

| Drive Motor | 1 HP – 3 HP AC Motor with VFD |

| Lifting Mechanism | Manual / Hydraulic / Electric |

| Optional Features | Operator Platform, LED Lights, Mobility Wheels |

Applications

Merger Conveyor

A Merger Conveyor is an intelligent material handling solution designed to merge two or more product lanes into a single stream, ensuring seamless flow and efficient downstream processing. Using belts, rollers, or chains, along with powered diverters or pop-up mechanisms, merger conveyors maintain product orientation and spacing while synchronizing speed and direction to avoid congestion or collision.

Merger conveyors are critical in sorting, packaging, order picking, and shipping operations, where goods from different sources need to be consolidated for labeling, palletizing, or loading. Fully integrable with WCS and sensor systems, they support high-speed, high-throughput operations with precision and minimal manual intervention.

Multi-Lane Merging

Combines two or more input lanes into a single output stream.Speed Synchronization

Uses variable speed drives (VFDs) to match product flow from different lanes.Pop-Up / Side Merge Units

Optional mechanisms ensure precise transfer and orientation.High-Speed Throughput

Capable of handling up to 120 items per minute depending on configuration.Product Alignment & Spacing Control

Maintains accurate gapping and position for downstream processing.Integration Ready

Compatible with scanners, labelers, sorters, and vision systems.

| Specification | Details |

|---|---|

| Conveyor Type | Belt / Roller / Chain merge systems |

| Input Lanes Supported | 30°/45°/customized. |

| Speed Range | Up to 60–90 m/min |

| Product Types | Cartons, trays, totes, parcels, bags |

| Drive Type | Motorized, VFD-controlled |

| Frame Material | Mild steel / SS / aluminum |

| Safety Systems | Photo sensors, emergency stop, anti-collision logic |

| Control Options | PLC / WCS / SCADA-integrated |

Applications

Belt Transfer Conveyor

Belt Transfer Conveyors are precision-engineered systems designed to move items seamlessly from one conveyor line to another, especially when transitioning between perpendicular or adjacent systems. Ideal for changing direction, merging or diverting goods, these conveyors ensure smooth, controlled movement of boxes, totes, parcels, or lightweight pallets with minimal friction and maximum accuracy.

These systems typically feature pop-up belts or angled belt sections that gently transfer products without damage. Whether used for 90° transfers, in-line sorting, or lane switching, belt transfer conveyors are a key component in automated material handling, enhancing throughput, space efficiency, and operational accuracy.

Smooth Right-Angle Transfers: Ideal for diverting or merging product flow.

High-Speed Operation: Supports quick movement with minimal product spacing.

Low Noise & Low Friction: Ensures quiet, smooth product handling.

Compact Footprint: Fits between existing conveyors or tight spaces.

Sensor Integration: Enables smart sorting and line control.

Modular Design: Easily integrates into new or existing conveyor systems.

| Specification | Details |

|---|---|

| Conveyor Type | Pop-up Belt / Angled Belt Transfer |

| Transfer Angle | 90°, 45°, or custom |

| Belt Material | PU / PVC / Anti-static belt options |

| Load Capacity | Up to 50 kg per unit |

| Speed Range | 10 – 60 m/min (variable via VFD) |

| Actuation Method | Pneumatic / Electric motor |

| Sensor Options | Photoelectric, Proximity, Barcode Integration |

| Frame Material | Aluminum / Powder-Coated Steel |

Applications

Curve Conveyor

Curve Conveyors are specially designed conveyor systems that allow materials to change direction smoothly while maintaining a continuous flow along a production or packaging line. Built with either rollers or belts, these conveyors guide goods around bends—typically at 30°, 45°, 60°, 90°, or even 180° angles—without manual handling or disruption to the workflow. Curve conveyors are essential for optimizing space in tight layouts, enabling more efficient use of facility floorplans by eliminating the need for sharp transitions or multiple transfer points.

Ideal for use in logistics, manufacturing, packaging, and sorting facilities, curve conveyors are available in powered or gravity variants and can be integrated seamlessly with straight conveyor lines. With their reliable design and flexible configuration options, they help reduce downtime, minimize handling errors, and improve productivity in complex material handling environments.

Smooth Direction Change: Allows seamless 30°, 45°, 60°, 90°, or custom bends.

Compact Footprint: Saves valuable floor space by eliminating unnecessary straight runs.

Multiple Conveyor Types: Available in belt or roller format—powered or gravity-based.

Customizable Width & Radius: Tailored to specific product dimensions and layout needs.

Consistent Product Flow: Reduces transition points and minimizes jamming or misalignment.

Safety & Durability: Built with high-grade materials and equipped with guards and guides.

| Radius of conveyors | 850mm minimum |

| Conveyor Width | 300 to 600mm or As per Carton/ Tote |

| Conveyor Height | 400 to 850mm / Customized |

| Curve Angles | 30, 45, 60, 90 &180 degree |

| Conveyor Speed | 10 to 15 m/ min |

| Payload | 10 to 100 Kg |

| Roller Dia | 38 to 60 mm (tapper type) |

| Structure | M S Powder coated/ S.S |

| Drive System | MDR, Chain Sprocket, Coard & Poly v type |

| Motor | MDR/SEW/Bonfiglioli/Reputed |

| Noise | Below 60 DB |

Applications

Horizontal Belt Conveyors

Horizontal Belt Conveyors are widely used mechanical systems that move materials and goods in a straight, level path across production floors, warehouses, and packaging areas. Using a continuous belt driven by pulleys, these conveyors are ideal for transporting items of various shapes and sizes—including boxes, parcels, components, and packaged goods. The flat and stable surface ensures smooth movement, making them perfect for handling delicate or irregularly shaped items.

Built for reliability and simplicity, horizontal belt conveyors improve efficiency by automating repetitive transport tasks and reducing manual handling. They are commonly used in assembly lines, sorting systems, and logistics operations. With customizable lengths, belt materials, and speeds, these conveyors can be tailored to meet the specific needs of any industrial process. Their quiet operation, energy efficiency, and low maintenance make them an excellent choice for both light and medium-duty material handling.

Flat, Level Transport: Ideal for horizontal movement of goods in production and storage environments.

Customizable Lengths & Widths: Tailored to fit available space and load dimensions.

Multiple Belt Options: Choose from PVC, PU, rubber, or fabric belts based on the application.

Variable Speed Control: Adjustable drive units for precise control over item flow.

Quiet Operation: Smooth belt motion with minimal noise, ideal for indoor environments.

Safety & Durability: Features like emergency stop switches and strong frames for long-term use.

| Conveyor Section Length | Up to 3000mm |

| Conveyor Belt Width | 200 to 1400mm |

| Conveyor Channel Width | 50 to 100mm |

| Belt Make | Hebasit/ AG group/ Ammeraal belt/ Reputed |

| Side guides | UHMWP/SS/MS |

| Conveyor Height | 400 to 850mm / Customized |

| Conveyor Speed | 30 m/min |

| Payload | 150 Kg |

| Belt supports | Roller / Flat Bed |

| Drive System | Shaft mtg Motor/ Chain Sprocket/ V belt |

| Motor | MDR/SEW/Bonfiglioli/Reputed |

| Noise | Below 60 DB |

Applications

Inclined Belt Conveyor

An Inclined Belt Conveyor is designed to efficiently move materials between different elevations—whether lifting goods from ground level to mezzanines, transferring items between floors, or feeding materials into packaging or sorting systems. This conveyor uses a continuous belt over a robust frame, often supported by cleats or sidewalls to prevent slippage on inclines.

Perfect for bulk material handling, boxed goods, or loose components, inclined conveyors are built to handle a variety of angles, capacities, and load types. Whether you’re moving cartons, totes, sacks, or irregular-shaped items, this solution ensures smooth, safe, and space-saving vertical transport within your facility.

Adjustable Incline Angles

Supports inclines up to 45° or more, depending on product type and belt configuration.Cleated or Rough-Top Belts

Prevents rollback of products during elevation.Modular Design

Easy to integrate with horizontal conveyors and sorting systems.Compact Footprint

Saves floor space while optimizing vertical movement.Sturdy Frame Construction

Built with mild steel, stainless steel, or aluminum for industrial durability.Low Maintenance Operation

Simple belt-drive mechanism with minimal wear components.

| Conveyor Belt Width | 200 to 1400mm |

| Conveyor inclination | 18 Degree |

| Conveyor Length | Up to 3000mm |

| Conveyor Channel Width | 50 to 100mm |

| Belt Make | Hebasit/ AG group/ Ammeraal belt/ Reputed |

| Side guides | UHMWP/SS/MS |

| Conveyor Height | 400 to 850mm / Customized |

| Conveyor Speed | 30 m/min |

| Payload | 150 Kg |

| Belt supports | Roller / Flat Bed |

| Drive System | Shaft mtg Motor/ Chain Sprocket/ V belt |

| Motor | MDR/SEW/Bonfiglioli/Reputed |

| Noise | Below 60 DB |

Applications

Roller Tyre Conveyor

Roller Tyre Conveyors are heavy-duty, specialized conveyor systems designed to transport large, round, or cylindrical objects such as vehicle tyres, drums, wheels, and similar components with ease and precision. These conveyors feature strong, evenly spaced rollers—often with urethane or rubberized surfaces—to provide a secure grip and gentle handling of tyres without deformation or slippage. Available in both powered and gravity versions, they can be tailored to accommodate tyres of various sizes and weights.

Widely used in tyre manufacturing, inspection, and assembly lines, Roller Tyre Conveyors are engineered for continuous, high-volume transport and can be integrated with automated loading, sorting, and stacking systems. Their robust construction and smooth handling capabilities ensure minimal product damage and enhanced throughput in demanding production environments.

Optimized for Round Items: Designed specifically for tyres, drums, wheels, and circular components.

Heavy-Duty Rollers: Steel or rubber-coated rollers for safe and stable product transport.

Custom Widths & Roller Pitch: Adjustable for various tyre diameters and weights.

Powered or Gravity Options: Choose based on load, workflow, and automation level.

Low Noise Operation: Smooth roller motion with noise-reducing coatings and bearings.

Integration Friendly: Works seamlessly with stackers, sorters, or robotic arms.

| Specification | Details |

|---|---|

| Conveyor Type | Roller Conveyor (Powered / Gravity) |

| Suitable for | Tyres, wheels, drums, and round items |

| Conveyor Width | 600 mm – 1500 mm (customizable) |

| Roller Diameter | 50 mm – 90 mm |

| Roller Material | MS, SS, or Rubber-Coated |

| Load Capacity | Up to 200 kg/meter |

| Frame Material | Mild Steel / SS304 / Aluminum |

| Drive Options | Chain Driven / Motorized Roller / Belt |

| Speed Range | 0.1 – 1.5 m/s (powered version) |

Applications

Belt Tyre Conveyor

Belt Tyre Conveyors are purpose-built conveyor systems designed for the smooth and reliable transportation of vehicle tyres, wheels, and similar cylindrical components. Unlike roller conveyors, these use a continuous, durable belt surface that provides uniform support across the entire tyre, ensuring stability and eliminating the risk of tipping, slipping, or jamming. This makes belt conveyors ideal for handling tyres at different production stages—especially where inclines, declines, or transitions between workstations are involved.

Equipped with high-friction, wear-resistant belts and heavy-duty frames, these conveyors are optimized for high-speed, high-volume tyre handling in production, inspection, and storage environments. They offer a quieter operation and are particularly useful in transporting tyres over long distances or on slopes. Whether in automated tyre factories or distribution centers, belt tyre conveyors help streamline logistics and increase operational efficiency.

Uniform Belt Surface: Ideal for transporting tyres without gaps or roller transitions.

High Traction Belts: Rubber or PU-coated belts for slip-resistant movement.

Custom Widths & Lengths: Adaptable to different tyre sizes and layout needs.

Incline/Decline Capable: Can be designed to move tyres vertically or diagonally.

Low Maintenance: Fewer moving parts, simple belt tracking, and reliable operation.

Quiet & Clean Operation: Minimal vibration and noise, ideal for indoor plants.

| Specification | Details |

|---|---|

| Conveyor Type | Flat Belt Conveyor for Tyres |

| Belt Material | Rubber, PU, PVC (anti-skid surface options) |

| Conveyor Width | 600 mm – 1500 mm (customizable) |

| Load Capacity | Up to 150 kg/meter |

| Frame Material | MS Powder-Coated / Stainless Steel |

| Speed Range | 0.1 – 2.5 m/s (variable with VFD) |

| Incline Capability | Up to 20° (with cleated belts if needed) |

| Power Supply | 220V / 380V AC, 3-phase |

| Drive Type | Center Drive / End Drive / Motorized Pulley |

Applications

Modular Conveyor

Modular Conveyors are highly versatile and flexible conveyor systems designed with interlocking plastic modules, allowing for easy customization, maintenance, and configuration. These systems are ideal for transporting a wide variety of products across straight lines, curves, inclines, and declines within a single integrated system. The modular belt surface ensures excellent product stability and is particularly suitable for items that require a smooth, flat conveying surface, such as packaged goods, containers, and food items.

Built with durability and hygiene in mind, modular conveyors are extensively used in industries where quick sanitation, layout changes, or product diversity is crucial. Their plug-and-play modularity allows users to replace damaged sections without dismantling the entire belt, leading to lower maintenance costs and higher uptime. They are a top choice for dynamic manufacturing and packaging environments.

Modular Belt Design: Easily replaceable plastic belt sections with minimal downtime.

Flexible Configuration: Supports straight runs, curves, inclines, and declines.

Durable Materials: Belts made from PP, PE, or acetal for high wear and chemical resistance.

Low Maintenance: No lubrication required; easy to clean and maintain.

Hygienic Options: Available in food-grade variants with open-hinge design for washdowns.

Quick Installation & Repair: Snap-fit components make assembly and repairs fast.

| Specification | Details |

|---|---|

| Conveyor Type | Modular Plastic Belt Conveyor |

| Belt Material | Polypropylene (PP), Polyethylene (PE), Acetal |

| Belt Width Range | 100 mm – 1500 mm (customizable) |

| Load Capacity | Up to 50 kg/meter |

| Speed Range | 0.2 – 2.5 m/s (adjustable) |

| Conveyor Configuration | Straight, Curve (30°–180°), Incline/Decline |

| Frame Material | SS304 / Aluminum / Mild Steel Powder-Coated |

| Hygiene Rating | Available in food-grade compliant models |

Applications

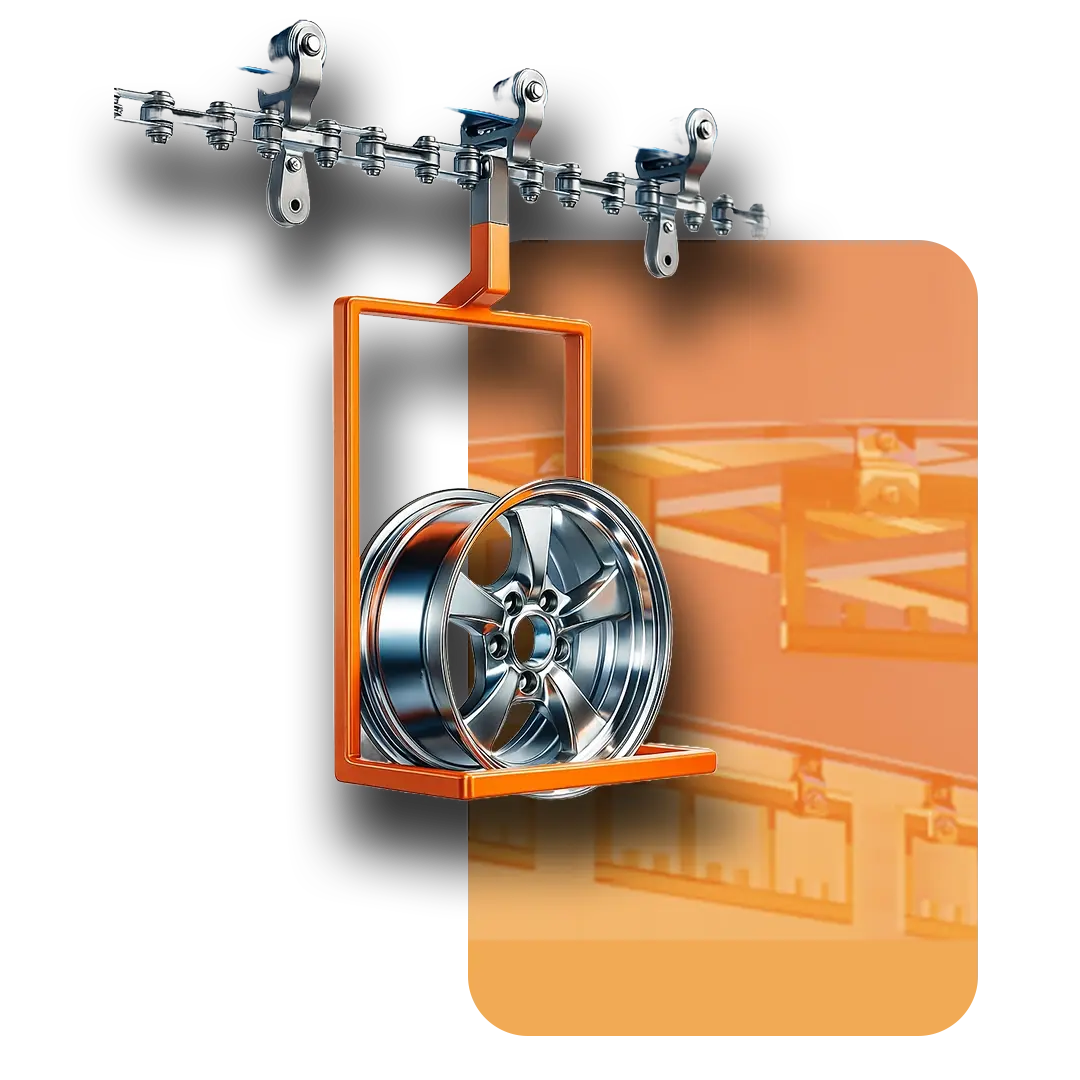

Power and Free Conveyor

Power and Free Conveyors are advanced overhead or floor-mounted conveyor systems that offer maximum flexibility, control, and efficiency for material handling operations. These systems consist of two tracks: a continuously moving “power” track and a separate “free” track where carriers or trolleys move independently. This design allows individual loads to start, stop, accumulate, buffer, divert, or switch lanes without halting the entire conveyor line.

Ideal for complex manufacturing and assembly environments, Power and Free Conveyors enable precise load management and sequencing for operations that demand variable speeds, zones, or routing paths. They are built to handle heavy loads and integrate seamlessly with robotics, sensors, and plant automation systems, making them an essential tool in just-in-time (JIT) production and lean manufacturing setups.

Dual Track System: Independent movement of carriers allows buffering and sorting.

Zone Control: Start/stop loads without affecting the rest of the line.

High Load Capacity: Handles medium to heavy-duty industrial parts.

Routing Flexibility: Allows switches, merges, and diverges for multi-line flow.

Customizable Carriers: Tailored for various part sizes and weights.

Automation Ready: Integrates with PLCs, sensors, and robotic systems.

Reliable Operation: Suitable for continuous duty with minimal downtime.

| Specification | Details |

|---|---|

| Conveyor Type | Overhead / Floor-Mounted Power and Free |

| Load Capacity per Carrier | 50 – 1000 kg (based on design) |

| Track Type | Enclosed track or I-beam |

| Speed Range | 1 – 30 m/min (adjustable) |

| Drive Motor | AC geared motor with inverter control |

| Switching Mechanism | Pneumatic or electric diverters |

| Accumulation Type | Stop pins, cam lifts, zone buffers |

| Control System | PLC or SCADA integrated |

Applications

Monorail Conveyor

Monorail Conveyors are single-track overhead material handling systems designed to move products smoothly along a defined path using a continuous or intermittent motion. The system consists of a rail (usually steel or aluminum) mounted overhead with powered or gravity-driven trolleys that carry loads across workstations. Ideal for streamlined, linear movement, monorail conveyors are used in environments where floor space optimization, clean operation, and precise routing are essential.

These systems offer high reliability and are often integrated into paint shops, assembly lines, and storage buffers, especially in industries requiring clean, suspended movement. Monorail conveyors reduce manual handling, improve ergonomics, and can be easily adapted for automated systems. Available in power-driven and manual versions, they are well-suited for transporting light to medium loads across defined paths.

Space-Saving Design: Overhead structure frees up valuable floor space.

Smooth & Controlled Movement: Ideal for delicate or sequential transport.

Manual or Powered Options: Customizable based on load and workflow.

Low Maintenance: Simple track system with minimal wear and tear.

Expandable Layouts: Easily extended or re-routed based on factory needs.

Safe Operation: Reduces manual lifting and floor traffic.

| Specification | Details |

|---|---|

| Conveyor Type | Overhead Monorail Conveyor |

| Track Material | Powder-Coated Steel / Aluminum |

| Load Capacity | 20 – 500 kg per trolley |

| Drive Type | Manual push, Chain-driven, or Power & Free |

| Speed Range | 2 – 30 m/min (powered models) |

| Track Configuration | Straight, curves, inclines, loops |

| Suspension Height | Adjustable as per ceiling/floor height |

| Control Options | Push-button, PLC, or automated sensors |

Applications

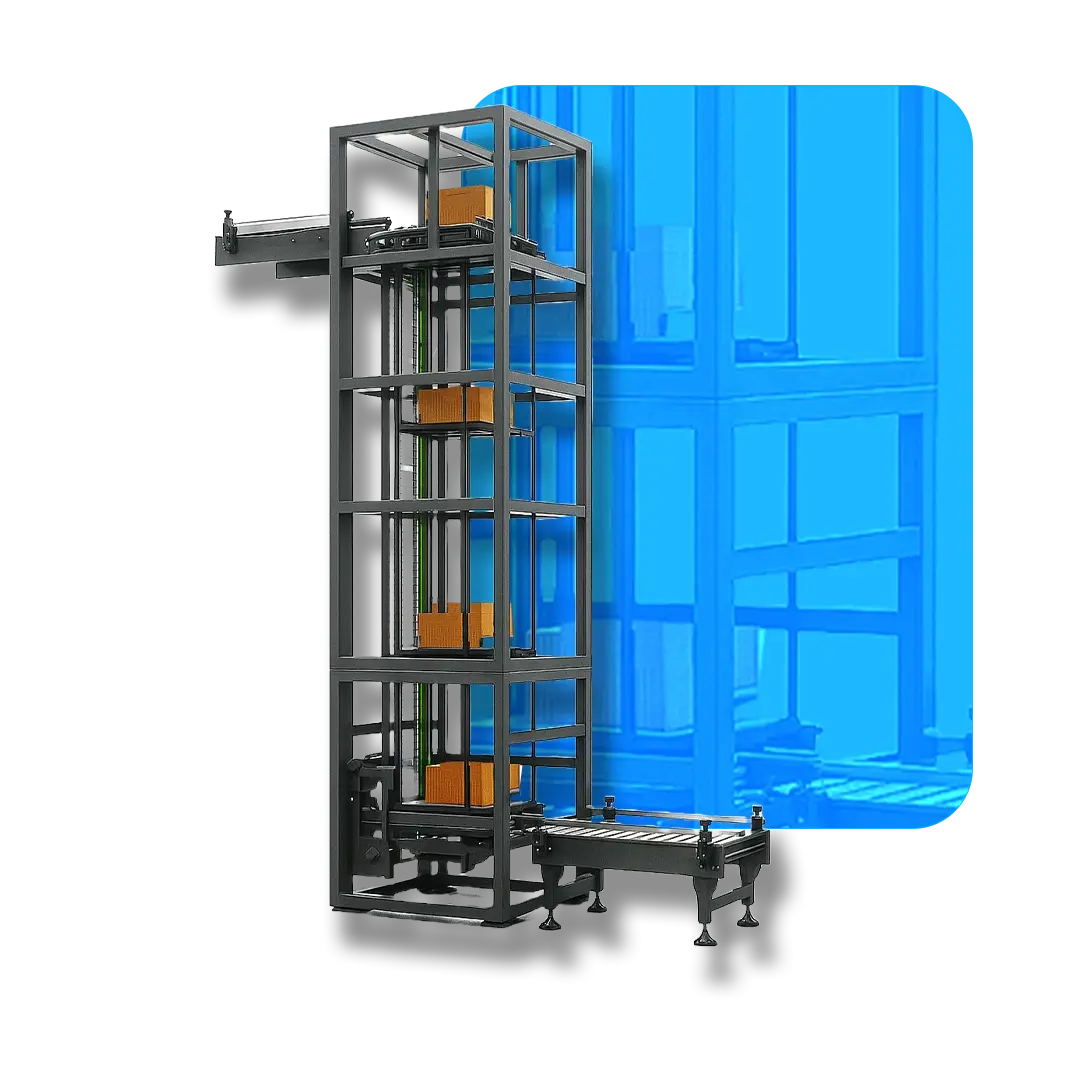

Tote/Carton Vertical Lift Conveyor

Tote or carton continuous vertical lifts are used to elevate or lower containers, boxes, trays, packages, sacks, bags, luggage and other articles with a solid surface between two levels, quickly and consistently at high capacity; on automatically loading platforms on a minimum footprint.

Multi-Tier Configuration: Supports 2 to 5 levels for maximum load utility.

Lightweight & Durable Frame: Made from aluminum or powder-coated steel.

Ergonomic Handle Design: Ensures easy maneuvering and control.

Heavy-Duty Casters: Swivel wheels with brakes for smooth, stable movement.

Customizable for Tote Sizes: Fits standard or custom plastic totes and bins.

Optional Accessories: Label holders, dividers, RFID tags, and docking slots.

| Continuous Lift | Specifications |

|---|---|

| Tote/Carton box Length | 250 to 1200 mm |

| Tote/Carton box Width | 1000 mm max |

| Lift Height | 15 mtr max. |

| Vertical Speed | 60 m/min |

| No of cycles per hour | 20 |

| Load Capacity | 20 to 60 Kg |

| Motor and Gear Box | MDR / SEW / Bonfiglioli / Reputed |

| Drive System | Chain / Belt |

| Lift Column | Single / Four |

| Structure | M S Powder coated |

| Control method | HMI |

| Noise | Below 70 DB |

| Safety System | Chain type |

Applications

Continuous Lift

A Continuous Lift—also known as a Continuous Vertical Conveyor—is a high-throughput vertical transport system designed to move cartons, totes, trays, or pallets between multiple levels continuously and efficiently. Unlike traditional elevators or lifts that handle one load at a time, a continuous lift allows for non-stop movement of multiple units in a vertical loop, significantly improving material flow in high-speed operations.

Ideal for airport baggage handling, automated warehouses, distribution centers, mezzanine systems, and manufacturing lines, this system is perfect for high-volume product elevation with minimal floor footprint, low noise, and seamless integration with horizontal conveyors or robotic systems.

Non-Stop Vertical Transport

Continuously lifts or lowers products without delay or batch handling.Multiple Floor Integration

Supports two or more levels, ideal for mezzanines or multi-tier racking.Gentle Product Handling

Designed to carry fragile goods without jerks or sudden stops.High Throughput

Can handle up to 2,000 units per hour, depending on configuration.Compact Footprint

Takes minimal floor space compared to spiral or incline conveyors.Modular & Scalable

Easily adjustable height, speed, and entry/exit points.

| Parameter | Specification |

|---|---|

| Tote/Carton Box Length | 250 to 1200 mm |

| Tote/Carton Box Width | 1000 mm max |

| Lift Height | Up to 30 meters |

| Vertical Speed | 60 m/min |

| No. of Cycles per Hour | 20 |

| Load Capacity | 20 to 60 Kg |

| Motor and Gear Box | MDR / SEW / Bonfiglioli / Reputed |

| Drive System | Chain / Belt |

| Lift Column | Single / Four |

| Structure | M S Powder Coated |

| Control Method | HMI |

| Noise | Below 70 DB |

| Safety System | Safety Fence, Light Curtains, EPB, LOTO, Area Sensors |